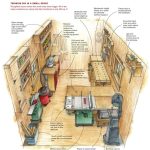

To layout a woodworking shop, plan the workflow, allocate space for tools, set up workstations efficiently, and prioritize safety measures. Designing an organized and functional layout is crucial for maximizing productivity and creating a safe working environment.

Properly arranging tools, workbenches, storage areas, and machinery will enhance workflow efficiency and overall productivity in a woodworking shop. By strategically positioning equipment, considering workflow patterns, and ensuring ample space for movement, you can create an optimized layout that enhances productivity and safety in your woodworking shop.

A well-thought-out layout contributes to a smoother workflow, minimizes clutter, and promotes a safer working environment for woodworkers of all levels.

Introduction To Woodworking Shop Layout

Woodworking shop layout is a crucial aspect that significantly impacts the efficiency and productivity of your woodworking projects. A well-organized layout can enhance workflow, improve safety, and optimize the use of space. In this guide, we’ll explore the key considerations and the importance of a well-organized space in woodworking shop layout.

The Importance Of A Well-organized Space

A well-organized woodworking shop is essential for a seamless and efficient workflow. It allows for easy access to tools and materials, minimizes clutter, and enhances safety. A clear and organized layout can also improve productivity and reduce the risk of accidents, contributing to a more enjoyable and efficient woodworking experience.

Key Considerations Before Starting

Before diving into the layout design of your woodworking shop, there are several key considerations to keep in mind. These include the available space, the types of woodworking projects you’ll be undertaking, the tools and machinery you’ll need, and the workflow that suits your working style. By carefully considering these factors, you can create a layout that maximizes efficiency and meets your specific woodworking needs.

The Essentials Of A Woodworking Shop

Designing a woodworking shop requires thorough planning to ensure maximum efficiency and functionality. Start by determining your workspace requirements, considering factors such as tool placement, storage, and lighting. Create a layout that works best for your workflow, and invest in quality tools and equipment to optimize your woodworking experience.

Setting up a woodworking shop can be an exciting and rewarding endeavor. However, to create a functional and efficient space, it’s crucial to have the right tools, equipment, and storage solutions in place. In this article, we will explore the essentials of a woodworking shop, focusing on core tools and equipment as well as storage solutions for materials and tools. By understanding these key elements, you can optimize your shop layout and enhance your woodworking experience.

Core Tools And Equipment

When it comes to woodworking, having the right tools is essential for achieving precise and high-quality results. Here are some core tools and equipment that should be part of every woodworking shop:

- Workbench: A sturdy workbench provides a solid surface for various woodworking tasks, such as cutting, shaping, and assembling.

- Power Tools: Power tools like a table saw, miter saw, band saw, and router enable you to make precise cuts and shape wood efficiently.

- Hand Tools: Essential hand tools include chisels, planes, screwdrivers, hammers, and clamps, which allow for more delicate and intricate woodworking tasks.

- Measuring and Marking Tools: Accurate measurements are crucial in woodworking. Tools such as a tape measure, combination square, marking gauge, and level ensure precise and consistent results.

- Safety Equipment: Safety should always be a priority in the woodworking shop. Safety glasses, ear protection, dust masks, and fire extinguishers are essential for protecting yourself and your workspace.

Storage Solutions For Materials And Tools

Efficient storage is vital to maintain an organized and clutter-free woodworking shop. Here are some storage solutions to consider:

- Shelving Units: Installing sturdy shelving units provides ample space for storing wood, tools, and other materials. Make sure to label and categorize items for easy access.

- Wall-mounted Tool Racks: Utilize wall space by installing tool racks to hang frequently used hand tools, keeping them within reach and well-organized.

- Drawer Cabinets: Opt for drawer cabinets to store smaller tools and accessories. Label each drawer to quickly locate specific items.

- Lumber Rack: A dedicated lumber rack ensures proper storage of various wood sizes and prevents warping or damage.

- Pegboard: Hang tools on a pegboard for easy visibility and accessibility. Arrange them according to size or function for added convenience.

By implementing these storage solutions, you can maximize your workspace, reduce clutter, and enhance overall efficiency in your woodworking shop.

Space Planning Strategies

When setting up a woodworking shop, space planning is a crucial step that can significantly impact productivity and efficiency. Properly organizing and utilizing the available space can make a substantial difference in the functionality of the workshop. Here are some space planning strategies to help you optimize your woodworking shop layout.

Measuring And Planning Your Space

Before diving into the layout, it’s essential to measure and assess your available space. Accurate measurements will guide the placement of equipment, workstations, and storage areas. Consider the dimensions of your larger tools and machinery when determining the layout of your shop. Sketching out a floor plan can help you visualize the arrangement and ensure that everything fits seamlessly.

Zoning: Dividing Your Space Effectively

Zoning your woodworking shop involves dividing the space into distinct functional areas. This approach helps in creating dedicated zones for specific tasks, such as cutting, assembly, finishing, and storage. By designating separate areas for different activities, you can minimize clutter and streamline workflow. Efficient zoning also contributes to a safer and more organized working environment.

Credit: thewoodwhisperer.com

Workflow Optimization

Workflow Optimization: Optimizing workflow in a woodworking shop is crucial for efficiency and productivity.

The Path Of Materials

Planning the layout of your shop to minimize unnecessary movements. Keep raw materials close to workstations for easy access.

Streamlining Your Woodworking Processes

- Implement a logical flow from one task to the next.

- Organize tools and equipment based on frequency of use.

- Utilize designated storage areas for each type of tool.

Lighting And Ventilation

Lighting and ventilation are crucial aspects when it comes to designing a woodworking shop layout. Proper lighting ensures clear visibility for precise cuts, while good ventilation helps to maintain a clean and healthy work environment. By strategically placing windows, skylights, and exhaust fans, you can create an optimal setup that enhances productivity and safety in your woodworking shop.

When it comes to setting up a woodworking shop, one of the most crucial aspects to consider is lighting and ventilation. Proper lighting ensures that you can see your work clearly and make accurate cuts, while proper ventilation keeps the air in your shop clean and safe to breathe. Let’s dive into the details of choosing the right lighting and ensuring proper ventilation and air quality.

Choosing The Right Lighting

Choosing the right lighting for your woodworking shop is essential for creating a productive and safe environment. Here are a few factors to consider:

- Brightness: Opt for lighting that provides ample brightness to illuminate your workspace effectively. LED lights are a popular choice for their energy efficiency and bright, white light.

- Color temperature: Consider the color temperature of the lights you choose. Cooler temperatures (around 5000K) provide a more natural daylight-like illumination, which can improve visibility and reduce eye strain.

- Placement: Strategically place your lights to minimize shadows and ensure even lighting across your work area. Consider overhead lighting as well as task lighting for specific workstations or tools.

- Adjustability: Look for lighting options that allow you to adjust the intensity or direction of the light. This flexibility can help you adapt the lighting to different tasks and enhance visibility.

By considering these factors and choosing the right lighting setup, you can create a well-lit woodworking shop that enhances your productivity and safety.

Ensuring Proper Ventilation And Air Quality

In addition to lighting, proper ventilation and air quality are vital for maintaining a healthy woodworking shop. Here are some steps you can take:

- Dust collection system: Install a dust collection system to capture and remove sawdust and other airborne particles. This helps prevent respiratory issues and keeps your workspace clean.

- Air filtration: Consider using an air filtration system to further improve the air quality in your shop. These systems remove fine particles that may escape the dust collection system, ensuring cleaner air for you to breathe.

- Natural ventilation: If possible, incorporate natural ventilation into your shop design. Windows or vents can help circulate fresh air and remove stale air, reducing the buildup of fumes or odors.

- Proper storage and disposal: Store chemicals, paints, and finishes in designated areas with proper ventilation to prevent the release of harmful vapors. Dispose of hazardous materials responsibly to avoid polluting the air.

By ensuring proper ventilation and air quality in your woodworking shop, you can create a healthier and more comfortable working environment for yourself.

Credit: www.youtube.com

Safety First

Prioritizing safety in your woodworking shop layout is crucial for preventing accidents and ensuring a secure work environment. Organize tools by category, maintain clear pathways, and install proper lighting for optimal visibility. Implement safety protocols and equip your space with necessary safety gear for a secure woodworking setup.

When it comes to setting up a woodworking shop, safety should be your top priority. Woodworking is an activity that involves sharp tools and heavy machinery, which means that accidents can happen if you’re not careful. By taking the time to create a safe working environment and investing in essential safety equipment, you can minimize the risk of injury and create a space that allows you to focus on your craft. In this section, we’ll cover some of the key steps you can take to ensure that safety always comes first in your woodworking shop.Essential Safety Equipment

Before you begin any woodworking project, it’s essential to have the right safety equipment on hand. This includes:- Eye and ear protection: Woodworking can create a lot of dust and noise, which can be harmful to your eyes and ears. Make sure you have a good pair of safety glasses and earplugs or earmuffs to protect yourself.

- Dust mask: Inhaling sawdust can be harmful to your lungs, so make sure you wear a dust mask to protect yourself.

- Gloves: When working with sharp tools, it’s important to protect your hands. Choose gloves that fit well and allow you to grip your tools securely.

- First-aid kit: Accidents can happen, so make sure you have a well-stocked first-aid kit on hand in case of an emergency.

Creating A Safe Working Environment

In addition to having the right safety equipment, it’s important to create a safe working environment in your woodworking shop. This includes:- Good lighting: Make sure your workspace is well-lit so you can see what you’re doing.

- Clean and organized space: A cluttered workspace can be hazardous, so make sure you keep your space clean and organized.

- Adequate space: Make sure you have enough room to maneuver your tools and equipment safely.

- Proper ventilation: Proper ventilation is essential to prevent the buildup of sawdust and fumes that can be harmful to your health.

Storage Solutions And Organization

Effective storage solutions and organization are essential for a well-functioning woodworking shop. A clutter-free and well-organized space not only enhances efficiency but also ensures a safer working environment. In this section, we will explore innovative storage ideas and the importance of regular maintenance in keeping your woodworking shop tidy.

Innovative Storage Ideas

When it comes to optimizing space in a woodworking shop, innovative storage solutions play a crucial role. Utilizing vertical space with wall-mounted storage racks and shelving units can maximize storage capacity without encroaching on the workspace. Modular storage systems that can be customized to fit specific tools and equipment provide flexibility and efficiency. Additionally, incorporating under-bench drawers and cabinets can keep frequently used tools within easy reach while maintaining a neat and organized shop layout.

Keeping Your Shop Tidy With Regular Maintenance

Maintaining a tidy woodworking shop requires consistent effort and attention to detail. Implementing a color-coded organization system for tools and materials can streamline the retrieval process and minimize clutter. Regularly inspecting and decluttering work surfaces, storage areas, and tool cabinets is essential for sustaining an organized environment. Furthermore, establishing a daily cleaning routine to sweep floors, clear debris, and return tools to their designated storage spaces can prevent accumulation of clutter and promote a safe and productive workspace.

The Tech-savvy Woodworking Shop

Integrating technology into a woodworking shop can significantly enhance efficiency and productivity. From software and apps to advanced machinery, the modern woodshop embraces the digital age to streamline operations and improve overall output.

Integrating Technology For Efficiency

Leveraging technology in a woodworking shop involves incorporating digital tools and equipment to optimize the layout, workflow, and production processes. This includes integrating automated machinery, digital measurement tools, and advanced workstations to enhance precision and speed.

Software And Apps To Streamline Operations

Utilizing specialized software and apps can revolutionize the management of a woodworking shop. From project management and inventory tracking to design and layout planning, these tools can streamline operations, improve communication, and increase overall efficiency.

Credit: www.pinterest.com

Frequently Asked Questions

How To Layout A Wood Workshop?

To layout a wood workshop, consider the space, workflow, storage, and safety. Plan for efficient tool placement and easy access. Ensure good lighting and proper ventilation for a comfortable working environment. Keep safety in mind when arranging machinery and workstations.

How To Design A Workshop Layout?

To design a workshop layout, follow these guidelines: 1. Determine the available space and take measurements. 2. Identify the equipment and tools needed for the workshop. 3. Plan the layout to maximize efficiency and workflow. 4. Consider safety regulations and ensure clear pathways.

5. Optimize storage solutions to keep the workshop organized.

How Do You Organize A Woodwork Workshop?

To organize a woodwork workshop, designate specific areas for cutting, assembling, and finishing. Install proper lighting and ventilation. Arrange tools and materials for easy access. Implement safety measures and provide storage for supplies. Keep the workspace clean and organized for efficiency and productivity.

What Is The Ideal Size For A Woodworking Workshop?

The ideal size for a woodworking workshop depends on the kind of work you intend to do. For small projects, a 10′ x 10′ area is sufficient. However, for larger pieces or commercial operations, a workspace of 20′ x 20′ or more is recommended.

Ultimately, the space should allow for easy movement, proper ventilation, and storage of materials and equipment.

Conclusion

In setting up your woodworking shop, focus on organization, safety, and efficiency. By following a well-thought-out plan, you can optimize your space and workflow. Remember to consider lighting, ventilation, and layout flexibility for a functional and productive workspace. Embrace creativity and practicality in designing your ideal woodworking shop.