To plan a woodworking shop, consider layout, tools, storage, lighting, safety, and workflow efficiency. Create a detailed blueprint.

Planning ensures a functional and organized workspace that maximizes productivity and enjoyment. By carefully considering these factors, you can design a woodworking shop that meets your needs and enhances your woodworking experience. Whether you are a beginner or a seasoned woodworker, a well-thought-out plan is essential for creating a successful woodworking shop.

In this blog post, we will discuss key steps and considerations to help you plan and set up your woodworking shop effectively. Let’s dive in and explore the exciting world of woodworking shop planning!

Introduction To Woodworking Shop Planning

When setting up a woodworking shop, careful planning is essential for creating an efficient and functional space. Consider factors such as layout, storage, and equipment placement to maximize productivity and safety. With thoughtful consideration and strategic organization, a well-planned woodworking shop can enhance workflow and overall enjoyment of the craft.

Key Considerations Before Starting

Planning a woodworking shop requires careful consideration of various factors to ensure a functional and efficient workspace. Before starting, it is important to assess your needs and preferences, as well as the available space and budget. Some key considerations include:- Size and layout of the workspace

- Type of woodworking projects you will be working on

- Tools and equipment you will need

- Storage solutions for materials and supplies

- Lighting and ventilation

- Electrical requirements

Importance Of A Well-planned Shop

A well-planned woodworking shop can make a significant difference in the quality of your work and your overall productivity. By carefully considering the layout, equipment, and storage solutions, you can create a workspace that is tailored to your needs and preferences, allowing you to work efficiently and comfortably. A well-planned shop can also help you save time and money in the long run by reducing the risk of accidents and injuries, minimizing waste, and ensuring that you have all the tools and supplies you need on hand. In conclusion, planning a woodworking shop requires careful consideration of various factors to ensure a functional and efficient workspace. A well-planned shop can make a significant difference in the quality of your work and your overall productivity. By considering the key factors and taking the time to plan your shop, you can create a workspace that is tailored to your needs and preferences, allowing you to work efficiently and comfortably.Selecting The Perfect Space

When planning a woodworking shop, selecting the perfect space is crucial for a smooth and efficient workflow. The right space can greatly impact the success of your woodworking projects. In this article, we will explore the space requirements for different projects and discuss the pros and cons of various locations.

Space Requirements For Different Projects

Woodworking projects vary in size and complexity, so it’s important to consider the space requirements based on the type of projects you plan to undertake. Here are some general guidelines:

| Project Type | Space Requirements |

|---|---|

| Small-scale projects | Can be accommodated in a smaller space like a garage or a shed. |

| Medium-scale projects | Require a dedicated area with enough room to comfortably work on larger pieces of wood. |

| Large-scale projects | Demand a spacious workshop with specialized equipment and ample storage for materials. |

By assessing the size and complexity of your woodworking projects, you can determine the ideal space requirements to set up your shop.

Pros And Cons Of Various Locations

Choosing the right location for your woodworking shop is essential for both convenience and functionality. Let’s explore the pros and cons of different locations:

Garage

Pros:

- Provides easy access to your tools and materials.

- Can utilize existing electrical and lighting systems.

- Offers protection from the elements.

Cons:

- May limit parking or storage space for vehicles.

- May require modifications to accommodate ventilation and dust collection systems.

Basement

Pros:

- Offers a climate-controlled environment for woodworking.

- Provides ample space for setting up a workshop.

- Generally has easy access to utilities.

Cons:

- May have limited natural lighting.

- May require additional insulation and soundproofing.

- May have limited access for moving larger pieces of wood and equipment.

Dedicated Outbuilding

Pros:

- Provides a separate and dedicated space for woodworking.

- Offers ample room for large-scale projects and storage.

- Minimizes noise and distractions from the main living area.

Cons:

- May involve additional costs for construction or renovation.

- Requires proper insulation and climate control.

- May have limited access to utilities.

Considering the pros and cons of each location will help you make an informed decision based on your specific needs and resources.

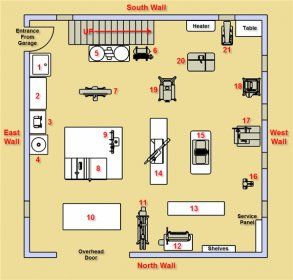

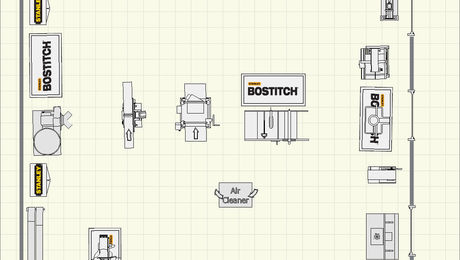

Layout Fundamentals

When planning the layout of a woodworking shop, it’s crucial to understand the fundamentals of efficient space design. The layout can significantly impact workflow, productivity, and safety. By focusing on the key concepts of the workflow triangle and zoning for efficiency, you can create a well-organized and functional woodworking shop.

The Workflow Triangle Concept

The workflow triangle is a fundamental principle in woodworking shop design. It involves organizing the three primary work areas—sawing, sanding, and assembly—in a triangular layout. Placing these areas in close proximity minimizes movement between tasks, streamlining the production process.

Zoning For Efficiency

Zoning the woodworking shop according to different functions can optimize efficiency. For instance, allocating a specific area for lumber storage, another for machinery, and a separate space for assembly and finishing can minimize disruptions and enhance productivity. Additionally, creating designated zones for specific woodworking tasks can further streamline operations.

Credit: www.youtube.com

Essential Tools And Equipment

When it comes to setting up a woodworking shop, having the right tools and equipment is crucial. Whether you’re a seasoned woodworker or just starting out, having the essential tools will make your woodworking projects more efficient and enjoyable. In this section, we will explore the must-have tools for your shop and smart storage solutions to keep your workspace organized.

Must-have Tools For Your Shop

When it comes to woodworking, having the right tools can make all the difference. Here are some must-have tools that every woodworker should consider:

- Table Saw: A table saw is the heart of any woodworking shop. It allows you to make precise cuts and is essential for ripping boards and cutting large sheets of plywood.

- Router: A router is a versatile tool that can be used for shaping edges, cutting joinery, and creating decorative details.

- Power Drill: A power drill is a versatile tool that can be used for drilling holes and driving screws. Look for one with adjustable speed settings and a comfortable grip.

- Compound Miter Saw: A compound miter saw is perfect for making angled cuts and crosscuts. It is essential for creating accurate miter joints and molding.

- Chisels: Chisels are essential for woodworking tasks such as carving, shaping, and creating mortises. Invest in a set of high-quality chisels in various sizes.

- Hand Planes: Hand planes are used for smoothing surfaces, flattening boards, and removing rough spots. They are available in different sizes and are essential for achieving a polished finish.

- Clamps: Clamps are indispensable for holding pieces together while the glue dries. They come in various sizes and styles, including bar clamps, pipe clamps, and spring clamps.

- Sanders: Sanders are used for smoothing surfaces and removing unwanted material. A random orbital sander and a belt sander are versatile options to consider.

Smart Storage Solutions

Keeping your woodworking shop organized is essential for efficiency and productivity. Here are some smart storage solutions to consider:

- Wall-Mounted Cabinets: Install wall-mounted cabinets to store smaller tools and accessories. This will help keep your workspace clutter-free and make it easier to find what you need.

- Pegboards: Hanging a pegboard on the wall provides a convenient way to store and display your most frequently used hand tools. It keeps them within easy reach and allows for quick organization.

- Tool Chests: Invest in a sturdy tool chest to store and protect your larger tools. Look for one with multiple drawers and compartments to keep everything organized.

- Rolling Carts: Rolling carts are great for storing and moving heavy tools or materials around the shop. They provide flexibility and can be easily moved to different work areas.

- Labeling System: Use a labeling system to identify the contents of drawers, cabinets, and bins. This will help you locate tools and materials quickly, saving you time and frustration.

By having the essential tools and implementing smart storage solutions in your woodworking shop, you can create a productive and organized workspace. Remember to invest in high-quality tools that will last and prioritize keeping your shop tidy for a more enjoyable woodworking experience.

Power And Lighting Considerations

When planning a woodworking shop, it’s crucial to carefully consider power and lighting requirements. Ensuring a safe and well-lit workspace is essential for productivity and precision. Let’s delve into the important power and lighting considerations for your woodworking shop.

Electrical Setup For Safety And Functionality

Adequate electrical setup is crucial for safety and functionality in a woodworking shop.

- Install sufficient outlets strategically to avoid overloading circuits.

- Consider dedicated circuits for heavy machinery to prevent power disruptions.

- Invest in ground fault circuit interrupters (GFCIs) to safeguard against electrical hazards.

- Label circuit breakers clearly for easy identification during emergencies.

- Regularly inspect and maintain electrical systems to prevent potential safety hazards.

Optimizing Lighting For Precision Work

Proper lighting is essential for accurate and detailed woodworking projects.

- Utilize a combination of overhead, task, and ambient lighting for comprehensive illumination.

- Consider natural light sources such as windows to enhance visibility and reduce eye strain.

- Install adjustable lighting fixtures to tailor brightness levels according to specific tasks.

- Choose LED lighting for energy efficiency, minimal heat emission, and long-lasting performance.

- Regularly clean and maintain lighting fixtures to ensure consistent brightness and clarity.

Dust Collection And Ventilation Systems

Efficient dust collection and ventilation systems are essential when planning a woodworking shop. Properly designed systems help to maintain a clean and healthy working environment by removing airborne dust particles and maintaining proper air circulation. By implementing these systems, woodworkers can ensure a safer and more productive workspace.

Designing An Effective Dust Collection System

Implement efficient dust collection system for woodworking shop.

Use a central dust collector to remove sawdust and debris.

Install ductwork to connect machines for optimal dust extraction.

Utilize cyclone separators to trap larger particles before filtration.

Ensuring Proper Airflow And Ventilation

Design shop layout to ensure airflow reaches all corners.

Install windows and vents for proper air circulation.

Use exhaust fans to remove airborne dust and maintain air quality.

Consider HVAC systems to regulate temperature and humidity.

Maximizing Shop Space

When planning a woodworking shop, maximizing space efficiency is crucial. Utilizing every inch effectively ensures a functional and organized workspace.

Creative Use Of Vertical Space

Vertical space is often underutilized but can significantly increase storage capacity. Install shelving units and wall-mounted cabinets to keep tools and materials off the floor.

Mobile Bases And Foldable Workbenches

Mobile bases allow for easy reconfiguration of the shop layout. Incorporating foldable workbenches provides flexibility for different project requirements.

Safety First: A Non-negotiable Priority

When setting up a woodworking shop, safety should always come first. Woodworking can be hazardous, so taking precautions is crucial to prevent accidents.

Safety Equipment Every Woodworker Needs

- Protective goggles to shield the eyes from wood chips and debris.

- Ear protection to reduce the noise from machinery and tools.

- Respirator or dust mask to avoid inhaling harmful sawdust particles.

- Work gloves to protect hands from splinters and cuts.

Establishing Safe Work Practices

- Keep work areas clean and clutter-free to prevent tripping hazards.

- Always use sharp tools, as dull tools can cause accidents.

- Secure workpieces properly before cutting or shaping them.

- Never leave power tools unattended when they are still running.

Personalizing Your Woodworking Shop

Customizing your woodworking shop involves meticulous planning to optimize space and workflow. Carefully consider the layout, storage solutions, and equipment placement to create an efficient and personalized workspace. Strategically organizing tools and materials can enhance productivity and creativity in your woodworking endeavors.

Adding Personal Touches For Inspiration

Personalizing your woodworking shop can boost creativity and motivation. Maintaining Flexibility for Future Changes is crucial for shop’s long-term success.

Credit: www.pinterest.com

Credit: www.finewoodworking.com

Frequently Asked Questions

What Are The Essential Tools For A Woodworking Shop?

To set up a woodworking shop, you’ll need basic tools such as a table saw, band saw, router, chisels, and measuring tools. These are essential for cutting, shaping, and measuring wood accurately, making them fundamental for any woodworking shop.

How Should I Layout My Woodworking Shop For Efficiency?

Efficient woodworking shop layout involves organizing tools and workstations for easy access and workflow. Consider factors like workflow, tool placement, and safety when planning your shop layout. An efficient layout can enhance productivity and make woodworking more enjoyable.

What Safety Measures Should I Follow In A Woodworking Shop?

Safety is paramount in a woodworking shop. Always wear protective gear such as safety glasses and ear protection. Keep your shop well-ventilated, use push sticks for cutting, and keep your workspace clean to prevent accidents and ensure a safe working environment.

What Are The Best Wood Types For A Woodworking Shop?

The best wood types for a woodworking shop depend on your projects. Common choices include pine, oak, maple, and walnut, each offering different characteristics and appearances. Consider the intended use and aesthetic preferences when selecting the wood for your projects.

Conclusion

Creating a woodworking shop is an exciting and fulfilling experience. By following the guidelines for planning a woodworking shop, you can ensure that your shop is functional, efficient, and safe. From selecting the right location to choosing the right tools and equipment, every step of the planning process is important.

With careful planning and attention to detail, you can create a woodworking shop that is tailored to your needs and allows you to pursue your passion for woodworking. Start planning your woodworking shop today and turn your dreams into reality!